Projects

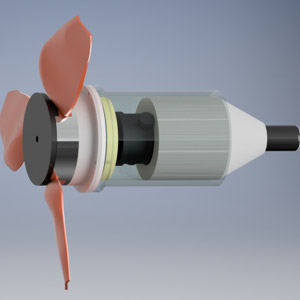

Hydro Charge

- Maintained the role of project manager which included organizing and planning for the team; kept team members accountable and ensured the project remained on track.

- Designed and built many different prototypes incorporating 3D modeling, ordering parts and materials, and building in RIT's machine shop.

- Wrote and executed test plans for testing the design was waterproof, functional electrically and mechanically, and durable.

- Outcome: The team was successful in creating an independent, waterproof, portable turbine which had the capability to charge a cell phone when rotating at a certain rpm.